Dallas Coil Handling and Press Feeding Equipment

It’s no secret that producing large amounts of precision parts from coil requires robust coil handling equipment up to and including:

- Powerful Coil Reels, Unwinders, Decoilers

- Precision Straighteners to correct edge wave and center buckle

- Accurate pneumatic or servo feeding equipment able feed accurately and quickly

- Coil Cradles, Up Enders, Levelers and Threaders + More

Complete Lines

Equipment

Complete Lines

CONVENTIONAL

Conventional

At Dallas Industries, our “conventional” lines are anything but. That’s because we listen to your objectives in order to provide the right equipment for each application.

SPACESAVER

Is floor space a concern? Then SpaceSaver may be the solution. We have three varieties. BackLoop SpaceSaver. UnderLoop SpaceSaver and LoopSelect SpaceSaver. They are available in coil weights from 10,000 to 60,000 lb. and widths from 12 in. to 72 in. Any SpaceSaver system can be equipped with SyncLoop™ to enhance the loop control.

Backloop Space Saver

BackLoop SpaceSaver™ feed lines can have a footprint as short as 20’. Featuring servo feeds with pull-thru straighteners and heavy-duty drives, BackLoop SpaceSaver™

Underloop SpaceSaver

UnderLoop SpaceSaver™ feed lines can have a footprint as short as 15’. These lines feature servo feeds with piloting pull-thru straighteners making them ideal for progressive die applications

LoopSelect SpaceSaver

Our most flexible option is our LoopSelect SpaceSaver.™ This design features a selectable loop control. Front loop mode allows processing of light-gauge material at long feed lengths and higher speeds. Back loop mode allows processing of heavygauge materials by allowing a clock-spring loop to form beneath the coil.

Equipment

SERVO FEEDS

At Dallas, we have 30+ years of servo feed design and manufacturing experience… and we continue to innovate. Each model of servo feed from Dallas has a pivoting upper roll lift for better gear mesh and even roll pressure, greasable roller bearings for maximum durability and comes with our exclusive ProfileSelect software that minimizes stress and jerk. Dallas servo feeds are available in models from 6 to 84 inches wide with material thickness capacities from .010 up to .750 and speeds up to 300 strokes per minute. Additional standard mechanical features include cluster gear driven upper rolls, pneumatic pilot release, heavy duty entry support roll assemblies with overhead trap rolls, AC brushless servo motors coupled to precision gear boxes, matte finished chrome feed rolls, and adjustable entry edge guides. Our servo feed controls include numerous standard features, along with options such as zig-zag motion, gag feeding and dual axis (push-pull) controls.

DRF 3

Widths from 6” to 36”

Solid, matte chrome surfaced rolls for superior grip

Pneumatic roll lift and pilot release

Solid, matte chrome surfaced rolls for superior grip

Pneumatic roll lift and pilot release

DRF 4 & 5

Widths from 12” to 48”

Dual cylinder pneumatic roll lift and pilot release

Adjustable height cabinet

Dual cylinder pneumatic roll lift and pilot release

Adjustable height cabinet

DRFH 6 & 8

Widths from 12” to 84”

Massive side plates with cartridge flange bearings

Adjustable height cabinet

Massive side plates with cartridge flange bearings

Adjustable height cabinet

ZIG-ZAG FEED

Zig-Zag feeds provide a great way to minimize material scrap when running circle blanks. Dallas’ reputation as a leader in zig zag feed technology is well-earned…

AIR FEEDS

Dallas Air Feeds

Dallas air feeds are available in 6 different models with capacities for standard and heavy-duty press feed requirements. Dallas air feeds will handle material widths up to 84” and run .010” to .500” material thickness.

Rapid-Air Feeds

Rapid-Air pioneered the first compact air feed with internal air circuitry, setting the technological and performance standards for the industry. The unique dual air valve system provides outstanding performance backed by reliability that has made Rapid-Air the recognized innovator and leader in air feed technology.

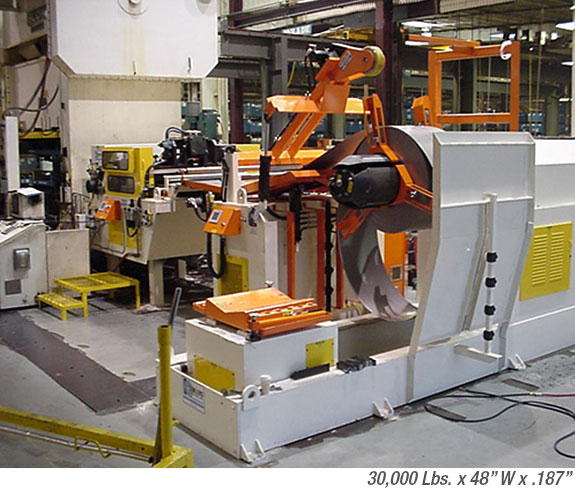

SERVO FEEDS – WITH PULL-THRU STRAIGHTENERS

Dallas servo feeds with pull-thru straighteners are engineered, built and have the power to easily handle materials up to 0.500 inch thick and widths from 6 up to 84 inches. They are best utilized in progressive die and transfer-type stamping operations. The close proximity of the straightener to the press tooling facilitates rapid flatness correction of coil stock as it is being processed. Pull-thru straighteners are available in 5, 7, 9, and 11 roll versions with roll diameters from 2 ¼” to 5”. Additional features can include LCD readouts, powered and air operated pinch rolls, automatic disengage clutch, chrome and polished rolls and even a pivoting straightening head for true pilot release.

Feeder / Straightener

This photo shows a cabinet mounted servo feed with pull thru straightener. This compact and affordable design is ideal for progressive die applications as it is equipped with our piloting……

Piloting Head Straightener

To add even more versatility to a servo feed with pull thru straightener, consider adding our unique Piloting Head Straightener….

POWERED STRAIGHTENERS

Dallas Powered Straighteners have a reputation for durability and running the most demanding materials while meeting and often exceeding material flatness requirements. Standard features include gear driven and individually adjustable straightening rolls, separate and larger cluster gear driven entry and exit pinch rolls, heavy side plates, bearings with inner and outer races, hardened rolls, heavy beveled gear or jack-type adjustment. Dallas drive packages include AC vector drives with controls that can be synchronized with the feed for advanced slack loop control. Depending on the application, a number of features/options can be supplied including: matte or smooth chrome finished pinch rolls, high flight back-up rolls, AutoSet automation package, and easy access opening for straightener roll cleaning.

Medium-Duty Straightener

Two straightener model available – DPS-2.25 & DPS-3.0

Widths from 6” to 48”

All rolls are solid (not tubing)

Widths from 6” to 48”

All rolls are solid (not tubing)

Heavy-Duty Straightener

Three straightener roll diameters available – DPS-3.5, DPS-4.2 & DPS-5.0

Widths from 12” to 84”

Available Hi-Flight backup rolls for maximum

Widths from 12” to 84”

Available Hi-Flight backup rolls for maximum

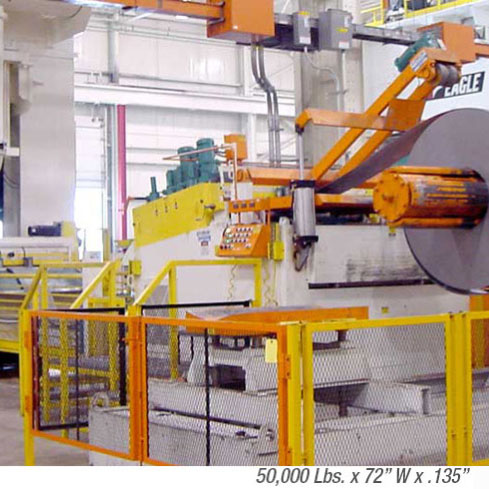

COIL REELS

Dallas engineers a wide variety of reel sizes and configurations to meet your current requirements as well as future needs. With coil weight capacities ranging from 1,500 to 60,000 lb. in stock width capacities from 12 to 84 in. wide, we have you covered. Reels can be manufactured as either motorized (AC drive) or pull-off (drag brake) depending on which is best suited for your application. Dallas reels are built with superb quality that includes the use of pillow-block bearings, heavy-duty cabinets, and only well-known brand names of supplied components. Standard features on our reel include wedge or link type expansion, manual or hydraulic expansion (and/or hydraulic threading drives), coil keepers and loop controls. Options include various loop controls (laser, photo electric, etc.), brakes designs including failsafe designs, hold down coil restrictors, and load cars.

Single Arm Reels

Widths to 84” wide

Coil Weights to 60,000 Lbs.

Manual and hydraulic mandrel expansion available, depending on size of reel.

Coil Weights to 60,000 Lbs.

Manual and hydraulic mandrel expansion available, depending on size of reel.

Single Arm Reels with Load Car

Ideal for simple loading and unloading of coils

Load car has either 18” or 24” of lift

Options for the load car includes narrow coil supports, remote pendant, auto coil centering and integrated coil upender.

Load car has either 18” or 24” of lift

Options for the load car includes narrow coil supports, remote pendant, auto coil centering and integrated coil upender.

Double Arm Reels

Widths to 60” wide (consult factory for wider)

Coil Weights to 20,000 Lbs.

Manual and hydraulic mandrel expansion available, depending on size of reel.

Coil Weights to 20,000 Lbs.

Manual and hydraulic mandrel expansion available, depending on size of reel.

COIL CRADLES

Dallas coil cradle capacities range from 4,000 to 50,000 lbs. and come standard with heavy-duty cabinets and side plates built to stand up to your toughest jobs. Features include full width powered nest rolls, adjustable side plates, AC variable speed drives, and cluster geared pinch rolls. Both pinch rolls and nest rolls are powered from a common cradle drive. Optional overhead, enclosed loop deflectors and guide-chutes direct the flow of the material and provide easy loading. Powered straighteners can be added to this configuration. Alternatively, cradle/straightener combo units (slack loop in front) are also available.

Cradle Straightener Combo

Cradle/Straightener Combo – This design combines the cradle and powered straightener into a single piece……

Cradle with Overhead Deflector

Cradle with Overhead Deflector – this is a common configuration for a cradle line. The coil is driven via the cradle nest rolls….

CONVENTIONAL

Conventional

At Dallas Industries, our “conventional” lines are anything but. That’s because we listen to your objectives in order to provide the right equipment for each application.

SPACESAVER

Is floor space a concern? Then SpaceSaver may be the solution. We have three varieties. BackLoop SpaceSaver. UnderLoop SpaceSaver and LoopSelect SpaceSaver. They are available in coil weights from 10,000 to 60,000 lb. and widths from 12 in. to 72 in. Any SpaceSaver system can be equipped with SyncLoop™ to enhance the loop control.

Backloop Space Saver

BackLoop SpaceSaver™ feed lines can have a footprint as short as 20’. Featuring servo feeds with pull-thru straighteners and heavy-duty drives, BackLoop SpaceSaver™

Underloop SpaceSaver

UnderLoop SpaceSaver™ feed lines can have a footprint as short as 15’. These lines feature servo feeds with piloting pull-thru straighteners making them ideal for progressive die applications

LoopSelect SpaceSaver

Our most flexible option is our LoopSelect SpaceSaver.™ This design features a selectable loop control. Front loop mode allows processing of light-gauge material at long feed lengths and higher speeds. Back loop mode allows processing of heavygauge materials by allowing a clock-spring loop to form beneath the coil.

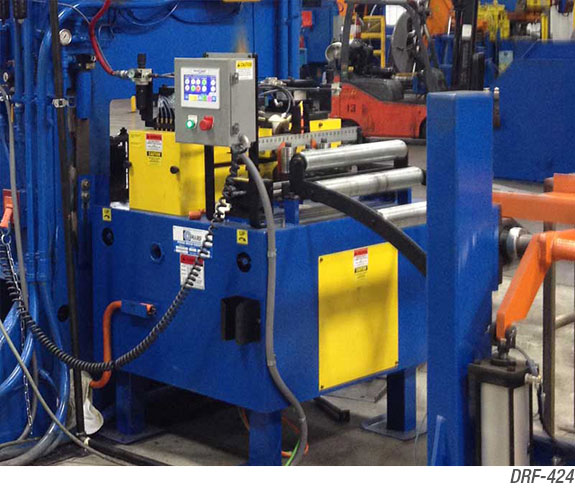

SERVO FEEDS

At Dallas, we have 30+ years of servo feed design and manufacturing experience… and we continue to innovate. Each model of servo feed from Dallas has a pivoting upper roll lift for better gear mesh and even roll pressure, greasable roller bearings for maximum durability and comes with our exclusive ProfileSelect software that minimizes stress and jerk. Dallas servo feeds are available in models from 6 to 84 inches wide with material thickness capacities from .010 up to .750 and speeds up to 300 strokes per minute. Additional standard mechanical features include cluster gear driven upper rolls, pneumatic pilot release, heavy duty entry support roll assemblies with overhead trap rolls, AC brushless servo motors coupled to precision gear boxes, matte finished chrome feed rolls, and adjustable entry edge guides. Our servo feed controls include numerous standard features, along with options such as zig-zag motion, gag feeding and dual axis (push-pull) controls.

DRF 3

Widths from 6” to 36”

Solid, matte chrome surfaced rolls for superior grip

Pneumatic roll lift and pilot release

Solid, matte chrome surfaced rolls for superior grip

Pneumatic roll lift and pilot release

DRF 4 & 5

Widths from 12” to 48”

Dual cylinder pneumatic roll lift and pilot release

Adjustable height cabinet

Dual cylinder pneumatic roll lift and pilot release

Adjustable height cabinet

DRFH 6 & 8

Widths from 12” to 84”

Massive side plates with cartridge flange bearings

Adjustable height cabinet

Massive side plates with cartridge flange bearings

Adjustable height cabinet

ZIG-ZAG FEED

Zig-Zag feeds provide a great way to minimize material scrap when running circle blanks. Dallas’ reputation as a leader in zig zag feed technology is well-earned…

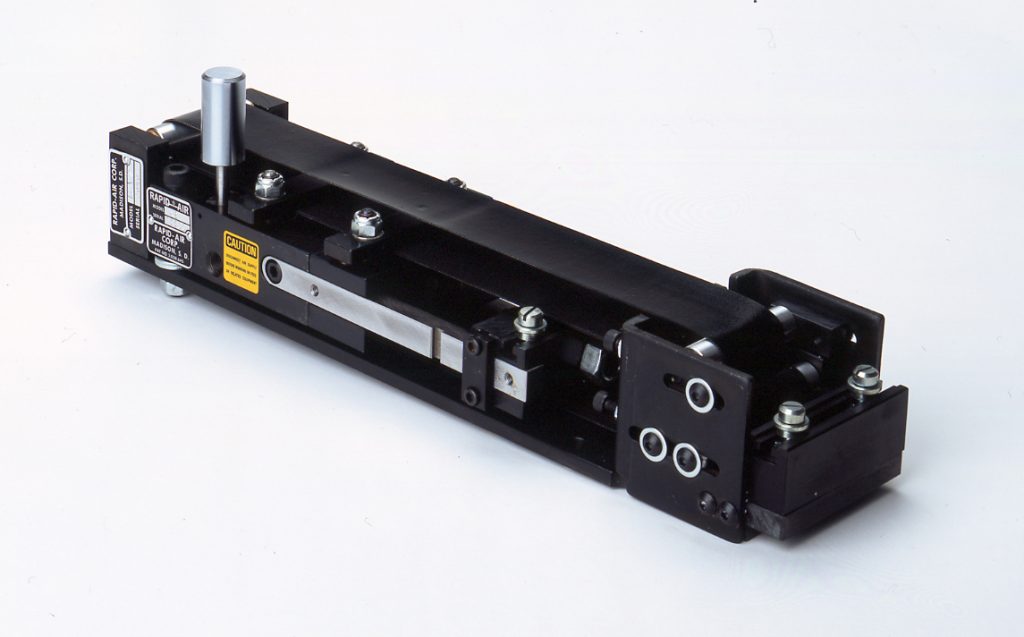

AIR FEEDS

Dallas Air Feeds

Dallas air feeds are available in 6 different models with capacities for standard and heavy-duty press feed requirements. Dallas air feeds will handle material widths up to 84” and run .010” to .500” material thickness.

Rapid-Air Feeds

Rapid-Air pioneered the first compact air feed with internal air circuitry, setting the technological and performance standards for the industry. The unique dual air valve system provides outstanding performance backed by reliability that has made Rapid-Air the recognized innovator and leader in air feed technology.

SERVO FEEDS – WITH PULL-THRU STRAIGHTENERS

Dallas servo feeds with pull-thru straighteners are engineered, built and have the power to easily handle materials up to 0.500 inch thick and widths from 6 up to 84 inches. They are best utilized in progressive die and transfer-type stamping operations. The close proximity of the straightener to the press tooling facilitates rapid flatness correction of coil stock as it is being processed. Pull-thru straighteners are available in 5, 7, 9, and 11 roll versions with roll diameters from 2 ¼” to 5”. Additional features can include LCD readouts, powered and air operated pinch rolls, automatic disengage clutch, chrome and polished rolls and even a pivoting straightening head for true pilot release.

Feeder / Straightener

This photo shows a cabinet mounted servo feed with pull thru straightener. This compact and affordable design is ideal for progressive die applications as it is equipped with our piloting……

Piloting Head Straightener

To add even more versatility to a servo feed with pull thru straightener, consider adding our unique Piloting Head Straightener….

POWERED STRAIGHTENERS

Dallas Powered Straighteners have a reputation for durability and running the most demanding materials while meeting and often exceeding material flatness requirements. Standard features include gear driven and individually adjustable straightening rolls, separate and larger cluster gear driven entry and exit pinch rolls, heavy side plates, bearings with inner and outer races, hardened rolls, heavy beveled gear or jack-type adjustment. Dallas drive packages include AC vector drives with controls that can be synchronized with the feed for advanced slack loop control. Depending on the application, a number of features/options can be supplied including: matte or smooth chrome finished pinch rolls, high flight back-up rolls, AutoSet automation package, and easy access opening for straightener roll cleaning.

Medium-Duty Straightener

Two straightener model available – DPS-2.25 & DPS-3.0

Widths from 6” to 48”

All rolls are solid (not tubing)

Widths from 6” to 48”

All rolls are solid (not tubing)

Heavy-Duty Straightener

Three straightener roll diameters available – DPS-3.5, DPS-4.2 & DPS-5.0

Widths from 12” to 84”

Available Hi-Flight backup rolls for maximum

Widths from 12” to 84”

Available Hi-Flight backup rolls for maximum

COIL REELS

Dallas engineers a wide variety of reel sizes and configurations to meet your current requirements as well as future needs. With coil weight capacities ranging from 1,500 to 60,000 lb. in stock width capacities from 12 to 84 in. wide, we have you covered. Reels can be manufactured as either motorized (AC drive) or pull-off (drag brake) depending on which is best suited for your application. Dallas reels are built with superb quality that includes the use of pillow-block bearings, heavy-duty cabinets, and only well-known brand names of supplied components. Standard features on our reel include wedge or link type expansion, manual or hydraulic expansion (and/or hydraulic threading drives), coil keepers and loop controls. Options include various loop controls (laser, photo electric, etc.), brakes designs including failsafe designs, hold down coil restrictors, and load cars.

Single Arm Reels

Widths to 84” wide

Coil Weights to 60,000 Lbs.

Manual and hydraulic mandrel expansion available, depending on size of reel.

Coil Weights to 60,000 Lbs.

Manual and hydraulic mandrel expansion available, depending on size of reel.

Single Arm Reels with Load Car

Ideal for simple loading and unloading of coils

Load car has either 18” or 24” of lift

Options for the load car includes narrow coil supports, remote pendant, auto coil centering and integrated coil upender.

Load car has either 18” or 24” of lift

Options for the load car includes narrow coil supports, remote pendant, auto coil centering and integrated coil upender.

Double Arm Reels

Widths to 60” wide (consult factory for wider)

Coil Weights to 20,000 Lbs.

Manual and hydraulic mandrel expansion available, depending on size of reel.

Coil Weights to 20,000 Lbs.

Manual and hydraulic mandrel expansion available, depending on size of reel.

COIL CRADLES

Dallas coil cradle capacities range from 4,000 to 50,000 lbs. and come standard with heavy-duty cabinets and side plates built to stand up to your toughest jobs. Features include full width powered nest rolls, adjustable side plates, AC variable speed drives, and cluster geared pinch rolls. Both pinch rolls and nest rolls are powered from a common cradle drive. Optional overhead, enclosed loop deflectors and guide-chutes direct the flow of the material and provide easy loading. Powered straighteners can be added to this configuration. Alternatively, cradle/straightener combo units (slack loop in front) are also available.

Cradle Straightener Combo

Cradle/Straightener Combo – This design combines the cradle and powered straightener into a single piece……

Cradle with Overhead Deflector

Cradle with Overhead Deflector – this is a common configuration for a cradle line. The coil is driven via the cradle nest rolls….

Need more help?

Our knowledgeable team is standing by to help you find solutions.