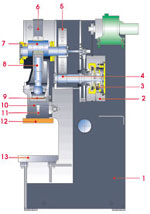

Description

The Stamtec OCP one-point gap frame press (a.k.a. OBG, OBS, OBI, or C-frame) is designed for stamping small parts at high single-stroking rates or in continuous mode, using either blanks or coil stock. The OCP metal stamping press provides all the features you expect to find in a world-class press, at a very competitive price, backed by a three-year (calendar-based) warranty without limitation.

TONNAGE RANGE: 27 – 330

DELIVERY TIME: In stock, or with quick delivery

Review the specs and advantages of our OCP Series gap frame press below, and then contact us for assistance in identifying the right mechanical press for your application.

Stamtec stamping press machines can be customized to meet a wider range of SPM, stroke, rating point (BDC), bed and other specifications and dimensions.