(Die Maker Solutions is proud to join forces and become the exclusive distributor for LINK Electric Punch Press Controls and Dallas Coil Feeding Equipment for Oklahoma and Texas starting Jan 1st 2018)

I’m truly humbled. When starting in this industry 5 years ago, it didn’t take long to discover LINK Press Controls and Dallas Feeds while out in my customers press rooms. While cutting my teeth in metal stamping sales, I was providing competitor products to Link/Dallas. You see, one of the jobs when selling a product is knowing the ‘ins and outs’ of competitive products and most importantly..their shortcomings. Problem was..after spending many of hours trying to find shortcomings in these two lines I discovered…there were none.

Link Systems produces and supports high quality press automation controls, tonnage monitoring, die protection, programmable limit switch and presence sensing devices for the metal forming industry. Unlike competitors, Link Press Controls are manufactured and assembled completely in the USA.

Link Systems produces and supports high quality press automation controls, tonnage monitoring, die protection, programmable limit switch and presence sensing devices for the metal forming industry. Unlike competitors, Link Press Controls are manufactured and assembled completely in the USA.

Headquartered in Nashville, TN, new and spare parts are stocked or at worst a day or two out due to assembly. In today’s’ world of manufacturing, speed is an absolute must and the top benefit of being a manufacturer versus an assembler; lead times are never a problem and customer production is kept up and running. For those wanting to learn more about LINK Press Controls check out

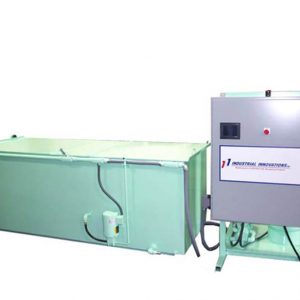

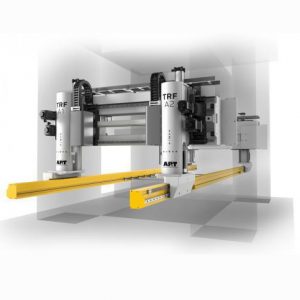

Dallas Industries products include both air feeds and servo feeds, pull-thru and powered straighteners, single and double end coil reels, load cars, coil cradles, threading tables, coil threading/restricting devices plus a host of other options.

Dallas Industries products include both air feeds and servo feeds, pull-thru and powered straighteners, single and double end coil reels, load cars, coil cradles, threading tables, coil threading/restricting devices plus a host of other options.

Dallas Industries has been successfully creating flexible press feeding and coil handling systems for over 50 years. During the initial years we produced state-of-the-art air feed equipment. Soon thereafter, we began developing an innovative new technology — servo driven press feed systems. Over time, our product line came to include a variety of coil straightening and handling equipment.

Today our products include both air feeds and servo feeds, pull-thru and powered straighteners, single and double end coil reels, load cars, coil cradles, threading tables, coil threading/restricting devices plus a host of other options. We design and manufacture many innovative and flexible systems, including our unique SpaceSaver™ lines which can cut floorspace requirements by 50%!

Whether you are looking for new or refurbished equipment, help with installation, line start-up, troubleshooting or maintenance services Dallas has you covered with outstanding factory support along with sales representatives located throughout North America. Generations of Innovation — to help you grow.

Again I am truly humbled to have the opportunity to take on and represent these two great lines and look forward to learning all that I can about them in order to sell them effectively to Texas and Oklahoma metal stampers.

Best, Jason Wilson

Die Maker Solutions

214-307-2411

I’m truly humbled. When starting in this industry 5 years ago, it didn’t take long to discover LINK Press Controls and Dallas Feeds while out in my customers press rooms. While cutting my teeth in metal stamping sales, I was providing competitor products to Link/Dallas. You see, one of the jobs when selling a product is knowing the ‘ins and outs’ of competitive products and most importantly..their shortcomings. Problem was..after spending many of hours trying to find shortcomings in these two lines I discovered…there were none.

Link Systems produces and supports high quality press automation controls, tonnage monitoring, die protection, programmable limit switch and presence sensing devices for the metal forming industry. Unlike competitors, Link Press Controls are manufactured and assembled completely in the USA.

Link Systems produces and supports high quality press automation controls, tonnage monitoring, die protection, programmable limit switch and presence sensing devices for the metal forming industry. Unlike competitors, Link Press Controls are manufactured and assembled completely in the USA.

Headquartered in Nashville, TN, new and spare parts are stocked or at worst a day or two out due to assembly. In today’s’ world of manufacturing, speed is an absolute must and the top benefit of being a manufacturer versus an assembler; lead times are never a problem and customer production is kept up and running. For those wanting to learn more about LINK Press Controls check out

Dallas Industries products include both air feeds and servo feeds, pull-thru and powered straighteners, single and double end coil reels, load cars, coil cradles, threading tables, coil threading/restricting devices plus a host of other options.

Dallas Industries products include both air feeds and servo feeds, pull-thru and powered straighteners, single and double end coil reels, load cars, coil cradles, threading tables, coil threading/restricting devices plus a host of other options.

Dallas Industries has been successfully creating flexible press feeding and coil handling systems for over 50 years. During the initial years we produced state-of-the-art air feed equipment. Soon thereafter, we began developing an innovative new technology — servo driven press feed systems. Over time, our product line came to include a variety of coil straightening and handling equipment.

Today our products include both air feeds and servo feeds, pull-thru and powered straighteners, single and double end coil reels, load cars, coil cradles, threading tables, coil threading/restricting devices plus a host of other options. We design and manufacture many innovative and flexible systems, including our unique SpaceSaver™ lines which can cut floorspace requirements by 50%!

Whether you are looking for new or refurbished equipment, help with installation, line start-up, troubleshooting or maintenance services Dallas has you covered with outstanding factory support along with sales representatives located throughout North America. Generations of Innovation — to help you grow.

Again I am truly humbled to have the opportunity to take on and represent these two great lines and look forward to learning all that I can about them in order to sell them effectively to Texas and Oklahoma metal stampers.

Best, Jason Wilson

Die Maker Solutions

214-307-2411