Our Equipment

-

RECLAIM-PRO I MSR – 11

Read more -

G2 Series Gap Frame Press

$1.00 Select options This product has multiple variants. The options may be chosen on the product page -

Pro-Mix™ V

Read more -

SPRA-RITE™ Lubricant Injector System Process Controller

Read more -

Pro-Mix™ V Double

Read more -

DRFH 6 & 8

Read more -

SpeedFeeder Transfer 4 × 40

Read more -

Monobar 80

Read more

Your Trusted Partner in Metal Stamping

Since its inception, DMS has helped manufacturing facilities streamline their metal handling operations through the strategic implementation of precision capital equipment, including, Metal Stamping Presses, Modular Transfer Systems, Coil Handling and Press Feeders, Press Controls and Safety Equipment, Sheet Metal Lubrication Equipment, Conveying Equipment and More!

However, before anything gets purchased or installed, we make sure that we know the full scope of your application. We also take the time to learn about your ‘pain points’, asking questions related to use cost, budget, past experiences with competitive lines, and plant context. This helps to give us a bigger picture, so that we know exactly how to best address your metal forming and stamping needs.

Use the options below to find the right equipment for you.

Would you like to fill in the application details (roughly 5 minutes) or skip and schedule to speak to a professional?

Optional Equipment

(Please check all that apply)

Punch Press Controls & Press Safety Guarding

Coil Handling and Press Feeding Equipment

Select the types of Feeding equipment you require

Quick Die Change Equipment

Select type of QDC Equipment

Machine Repair Or Other Services

What do you require?

Need more help?

Equipment Categories

Click here for details

Click here for details

Click here for details

Click here for details

Click here for details

Click here for details

Case Studies

A new NST press from Dayton, OH, U.S.-based AIDA helps Empire Comfort Systems keep upwith the...

Read More

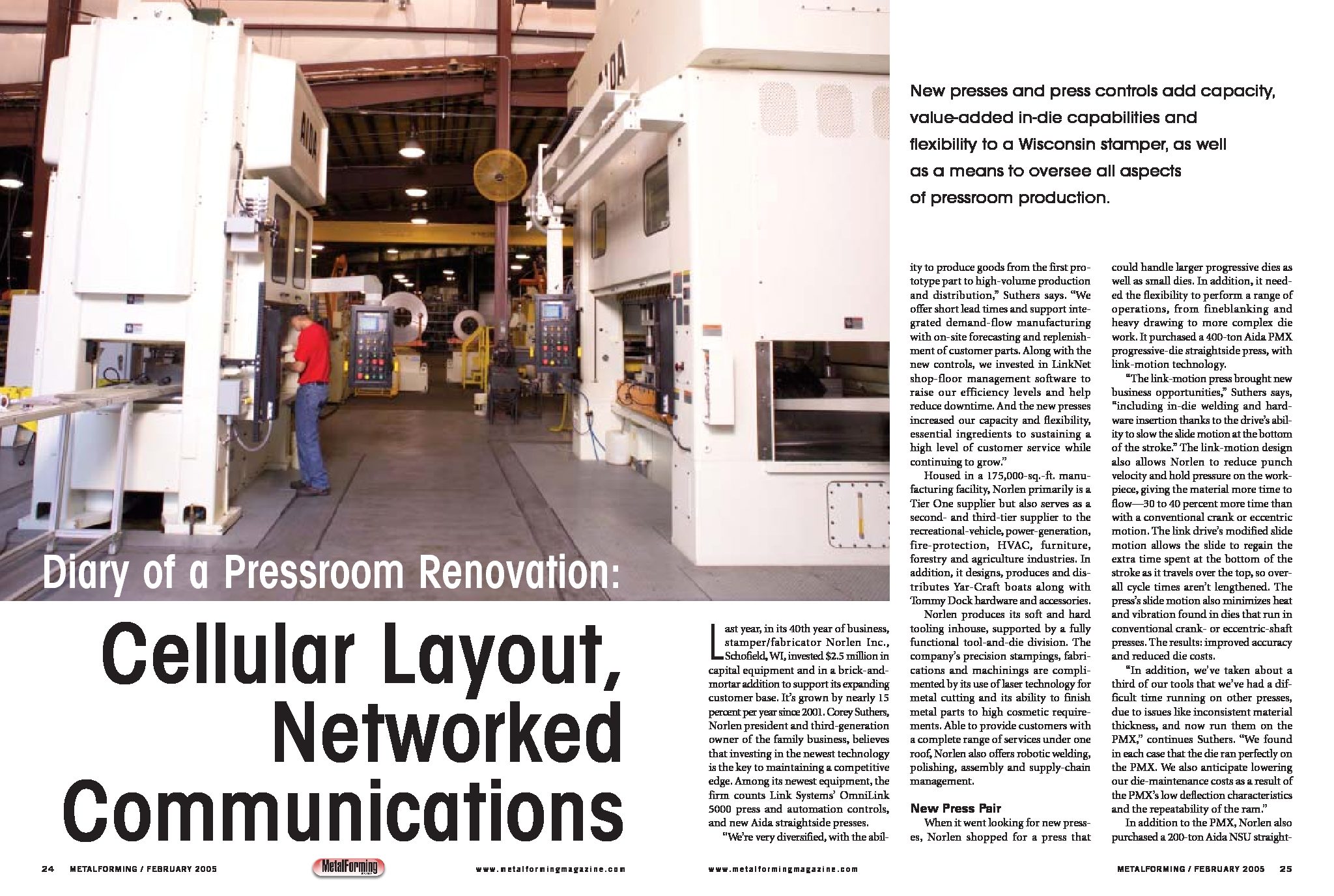

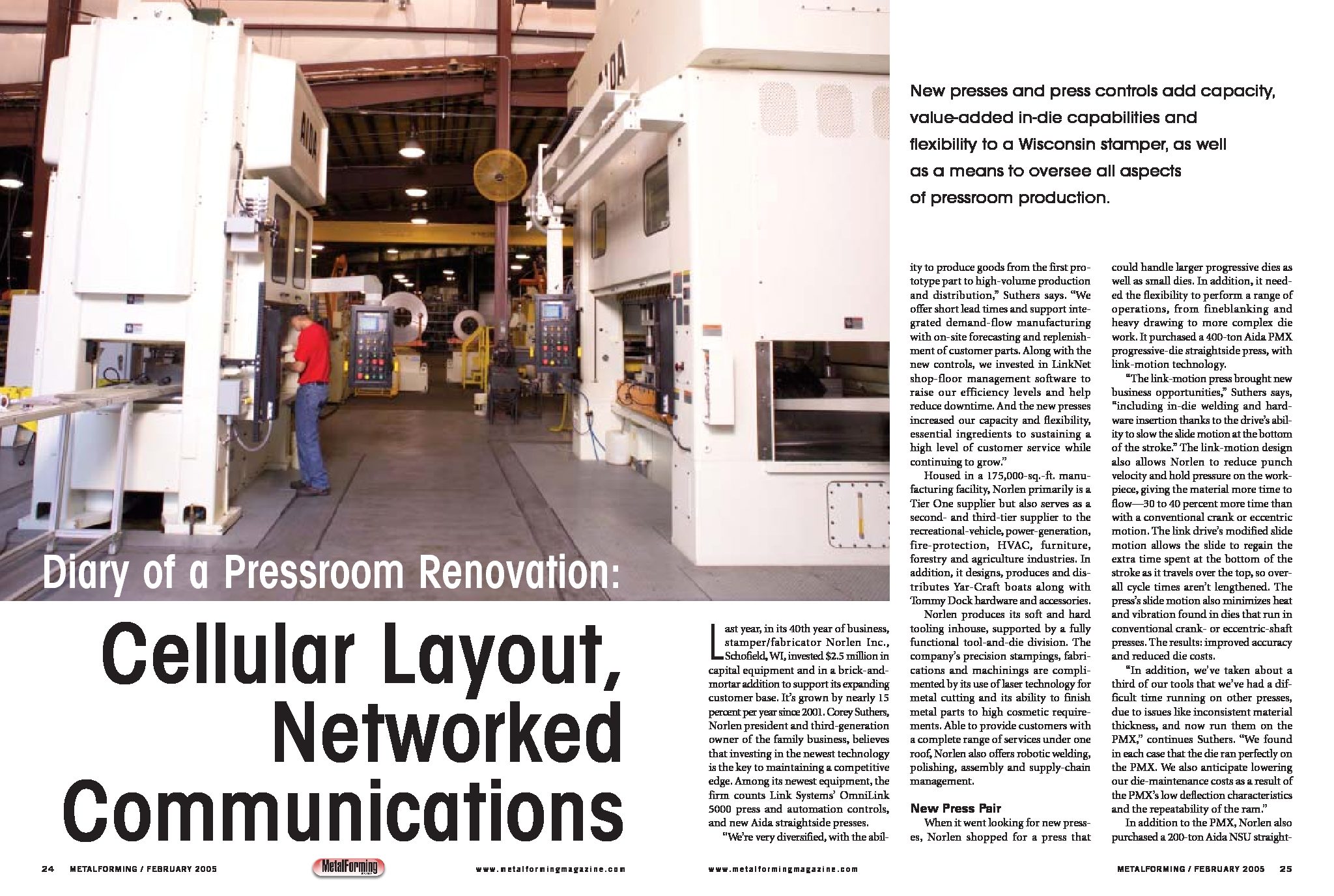

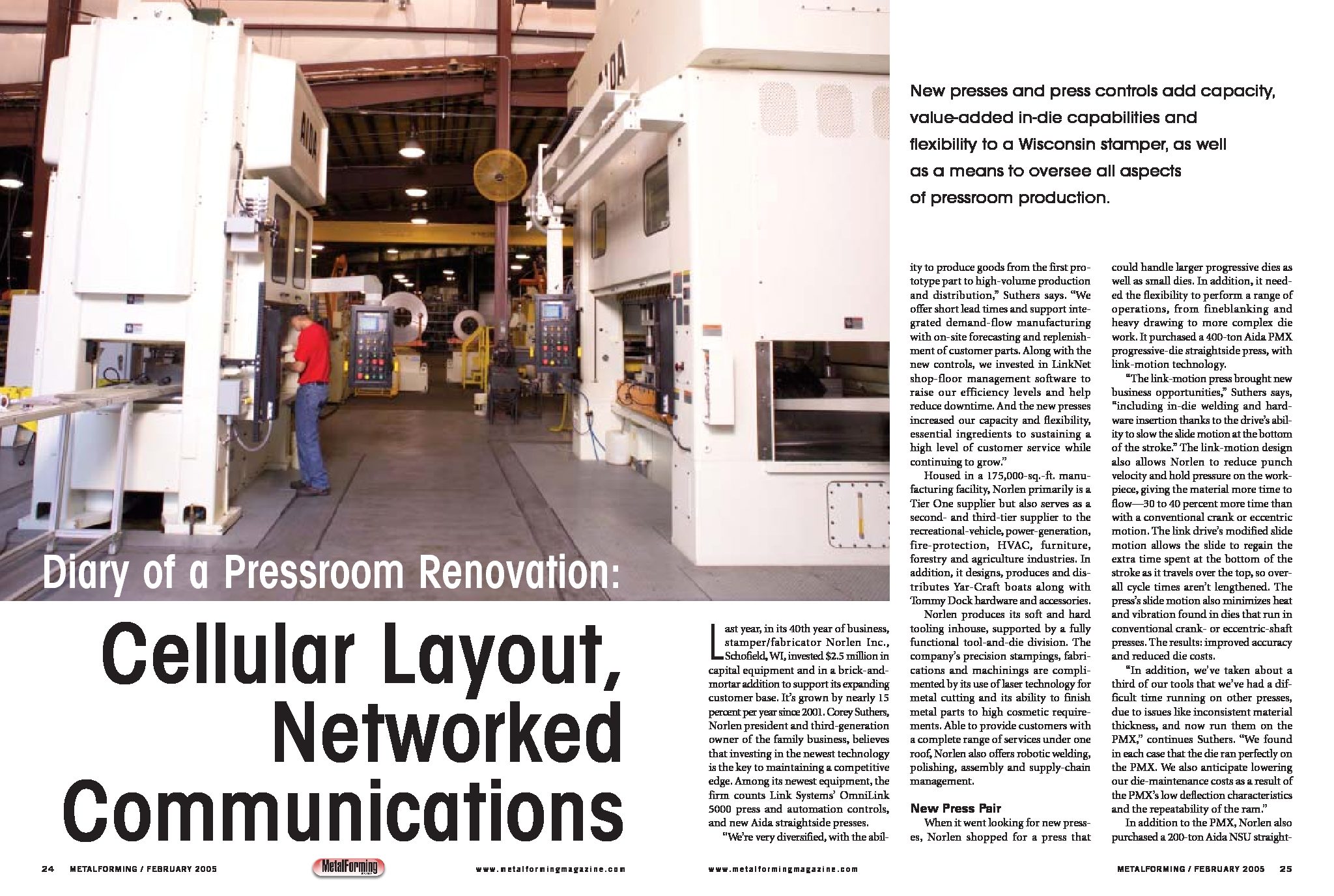

New presses and press controls add capacity, value-added in-die capabilities and flexibility to a Wisconsin stamper...

Read More

In-Die-Sensing steps up in an industry where more parts are considered critical...

Read More

A new NST press from Dayton, OH, U.S.-based AIDA helps Empire Comfort Systems keep upwith the...

Read More

New presses and press controls add capacity, value-added in-die capabilities and flexibility to a Wisconsin stamper...

Read More

In-Die-Sensing steps up in an industry where more parts are considered critical...

Read More

AIDA - Pressing for Growth

A new NST press from Dayton, OH, U.S.-based AIDA helps Empire Comfort Systems keep upwith the...

Press controls add capacity

New presses and press controls add capacity, value-added in-die capabilities and flexibility to a Wisconsin stamper...

The Quest for Zero Scrap

In-Die-Sensing steps up in an industry where more parts are considered critical...