Stamping Presses

MECHANICAL, FORGING, & SERVO PRESSES FOR YOUR COMPLETE PRESS-LINE SOLUTION

Known worldwide for quality, reliability and proven performance, Stamtec has built thousands of stamping presses every year for over six decades.

Stamtec, through our parent company, is one of the largest press builders in the world, with more than 60,000 presses sold; 1500 employees; 6,500,000 square feet of manufacturing floor space and with facilities in the U.S., Taiwan, China and Mexico, producing more than 3,000 presses per year.

We are one of the most prominent and proven press manufacturers in the world. Our presses are acknowledged worldwide throughout the metal stamping industry for quality, reliability and proven performance.

For more than 70 years, we have recognized our customers as long-term partners, growing together, and our presses are now operating in over 40 countries around the world. Take advantage of this global strength, and grow with us as we grow with you.

Some points which we believe set us apart from the crowd:

- Stamtec has one of the largest in-stock inventory of mechanical presses in the U.S.

- Stamtec has been in business since 1949 as a mechanical press manufacturer with nearly 40 years in the U.S. market.

- Our presses are manufactured by our own employees in our own factory, and are known worldwide for quality, reliability and proven performance.

- Electrical and mechanical engineers, sales/application and service/support personnel at our 72,000 sq. ft. logistics and assembly facility in Manchester, TN (one hour southeast of Nashville, TN).

We have the capabilities for complete turn-key integration of press, quick die change, coil feedline, transfer system and other peripheral equipment.

We offer competitive pricing for a well-built, high-performance product.

For more information, download our Corporate Catalog.

STAMTEC Metal Stamping Presses

G2 Series Gap Frame Press

OCP Series Gap Frame Press

GTX Series 2-Point Straight Side Press

S2 Series 2-Point Straight Side Press

Mechanical Gap Frame Press | Single Point | 35 – 250 Metric Tons Capacity

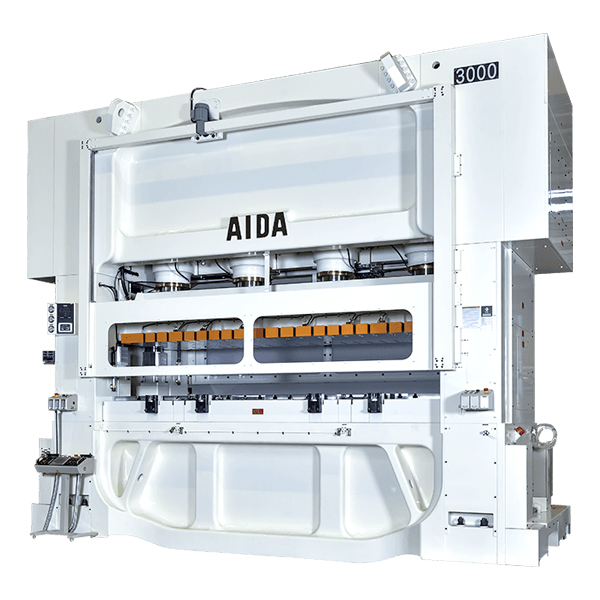

Frame Press Like all AIDA NC-series gap frame presses, the NC1 Single Point Gap Frame Press uses a welded steel frame, cast iron slide, and over-sized cast steel bolsters. This enables the press to deliver angular frame deflection that can be as little as 1/3 of competitive models, ensuring longer die life and higher part quality.